The Ultimate Guide to Glass Laser Cutting

Laser cutting has emerged as a transformative technology in precision manufacturing. This process offers unparalleled capabilities in cutting various materials with high accuracy and efficiency. In the realm of glass fabrication, laser cutting plays a crucial role in creating intricate designs, precise components, and functional parts across diverse industries. This article delves into the complexities of glass laser cutting, its technological aspects, the cutting process, applications across different sectors, and future trends shaping its evolution.

Understanding The Glass Laser Cutting Process

Glass laser cutting employs high-powered CO2 or Nd lasers to precisely cut through glass sheets of varying thicknesses. The process begins with meticulous preparation of the glass surface to ensure optimal conditions for laser interaction. This preparation involves cleaning the glass thoroughly to remove any contaminants that could affect the cutting quality.

Key Steps

- Preparation: The glass surface is cleaned to remove dust, oils, and other impurities. This step is critical as clean surfaces facilitate better laser absorption and ensure consistent cutting quality.

- Setting Parameters: Laser cutting parameters are then set based on the type and thickness of the glass. These parameters include laser power, cutting speed, focal length of the lens, and type of assist gas. Calibration of these settings is essential to achieve precise cuts without damaging the glass surface.

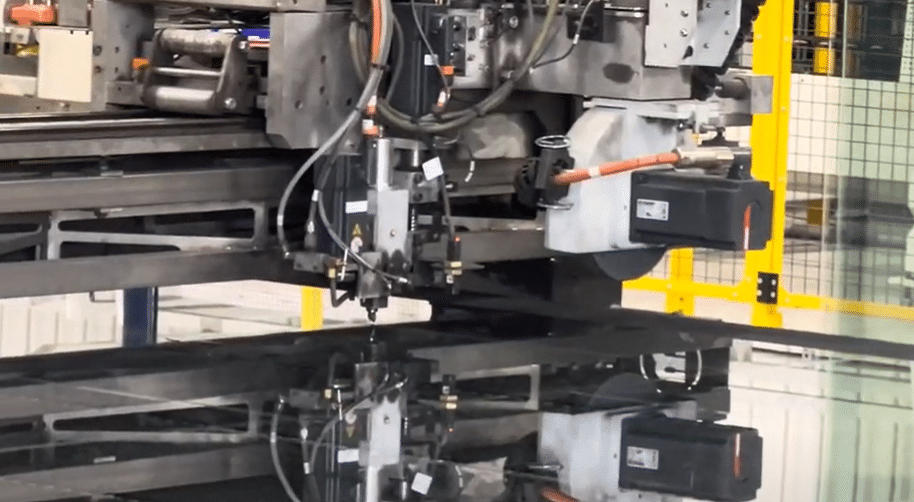

- Laser Beam Focusing: Once parameters are set, the laser beam is focused through a series of mirrors and a focusing lens. The focused beam achieves a high-energy density necessary to heat the glass to its melting or vaporization point along the predetermined cutting path.

- Cutting Process: The focused laser beam cuts through the glass by melting or vaporizing the material along the defined path. For thicker glass, the laser may first score the surface before completing the cut through a combination of laser energy and mechanical breaking.

- Assist Gases: Assist gases such as nitrogen or oxygen are often used during the cutting process to improve cutting efficiency and edge quality. Nitrogen, for instance, helps prevent oxidation of the cut edges, resulting in cleaner cuts and minimizing the need for post-processing.

Applications of Laser-Cut Glass

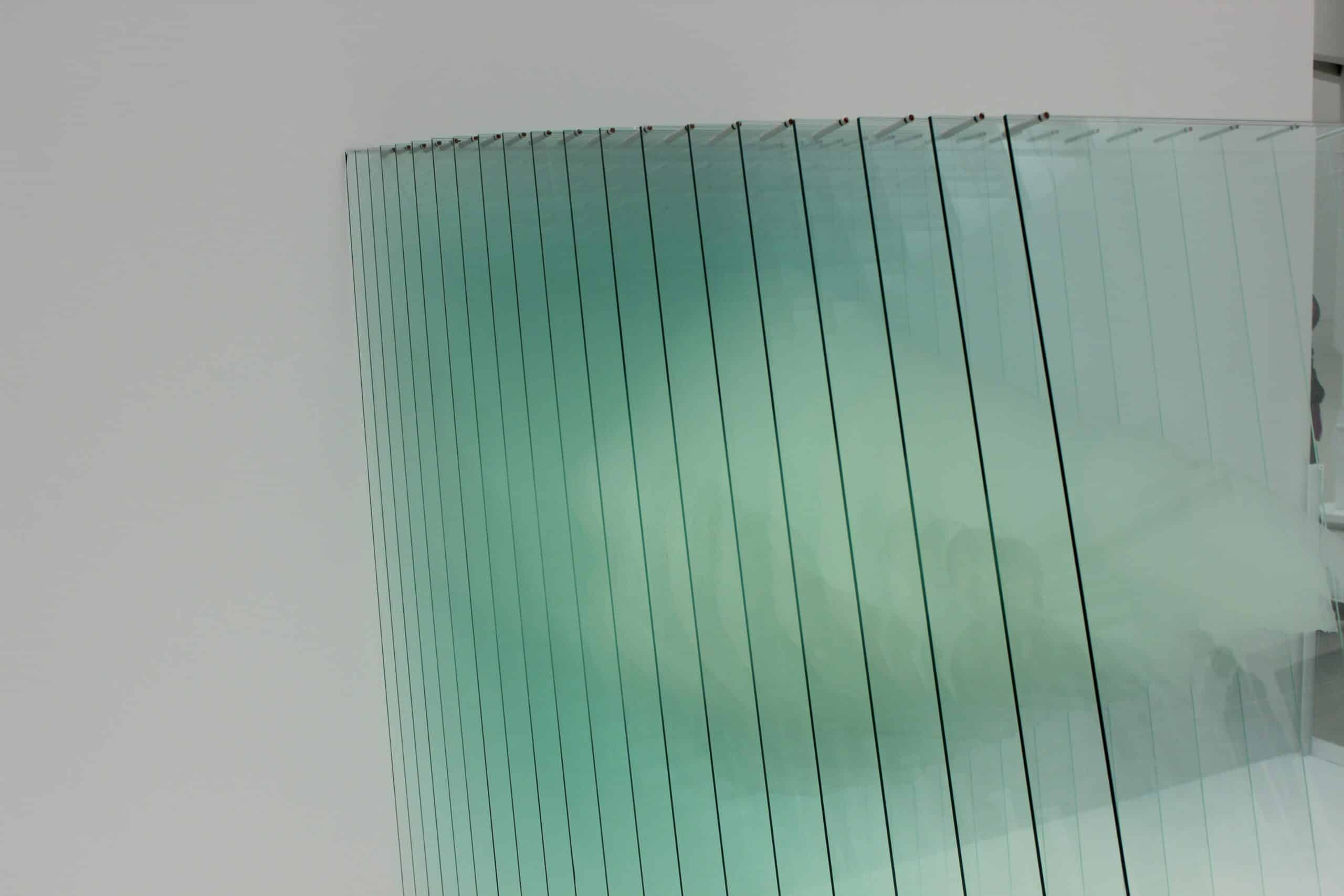

Laser-cut glass finds extensive applications across a wide range of industries due to a number of factors. Its precision, versatility, and ability to create complex designs with fine details. Some prominent applications include:

- Architectural Applications: Laser-cut glass is used in architectural design for creating decorative elements, facades, partitions, and interior features that demand both aesthetic appeal and structural integrity.

- Automotive Industry: Precision-cut glass components are crucial in automotive manufacturing, including windshields, windows, and interior glass panels. Laser cutting ensures precise fitting and enhances overall vehicle safety and aesthetics.

- Electronics: Glass substrates for electronic devices such as LCD panels, touchscreens, and optical components benefit from laser cutting’s ability to create precise cutouts and intricate patterns essential for functionality and visual clarity.

- Art and Design: Artists and designers utilize laser cutting to push the boundaries of creativity in glass artworks, sculptures, and decorative pieces. The technology allows for intricate designs and customizations that traditional cutting methods cannot achieve.

- Medical and Scientific Instruments: Glass components for medical devices, laboratory equipment, and scientific instruments require precise dimensions and smooth edges, making laser cutting an ideal choice to meet these stringent requirements.

Advantages

The adoption of laser cutting technology for glass offers several distinct advantages:

- Precision and Accuracy: Laser cutting enables highly precise cuts with minimal kerf widths. This allows for intricate designs and tight tolerances that traditional cutting methods may struggle to achieve.

- Efficiency: The non-contact nature of laser cutting and high cutting speeds contribute to faster production times and reduced operational costs.

- Minimal Material Waste: Laser cutting produces narrow cuts with minimal material wastage, maximizing material utilization and reducing overall production costs.

- Versatility: Laser cutting can accommodate a wide range of glass types and thicknesses, from thin sheets to thick plates, without compromising cutting quality or efficiency.

Challenges and Considerations

While laser cutting offers numerous benefits for glass fabrication, it also presents challenges that need to be addressed:

- Brittleness: Glass is inherently brittle and can crack or chip if not cut under controlled conditions. Proper handling and setting of cutting parameters are essential to minimize these risks.

- Initial Investment: The initial investment in laser cutting equipment and setup can be substantial. However, the long-term benefits in terms of efficiency, quality, and versatility often outweigh these initial costs.

- Complexity: Achieving optimal cutting parameters for different types of glass and thicknesses requires expertise and experimentation. Continuous refinement of cutting techniques is necessary to ensure consistent and high-quality results.

Future Trends in Glass Laser Cutting

The future of glass laser cutting is poised for significant advancements driven by technological innovations and industry demands:

- Advancements in Laser Technology: Ongoing advancements in laser sources, including improved beam quality, higher power densities, and enhanced control systems, will further enhance cutting precision and efficiency.

- Automation and Robotics: Integration of automation and robotics into laser cutting systems will streamline operations, reduce manual intervention, and increase production throughput.

- AI and Adaptive Cutting: Artificial intelligence (AI) algorithms will play a crucial role in optimizing cutting parameters in real-time, adapting to variations in material properties and environmental conditions for optimal cutting performance.

- Energy Efficiency: Continued focus on energy-efficient laser sources and cutting processes will reduce operational costs and environmental impact, making laser cutting a more sustainable manufacturing solution.

Glass laser cutting stands at the forefront of modern manufacturing technology. It offers unmatched capabilities in creating precise, intricate, and functional glass components across various industries. From architectural marvels to high-tech electronics and intricate artworks, laser-cut glass continues to push the boundaries of design and functionality. For businesses and industries looking to leverage the benefits of glass laser cutting, understanding these processes is crucial.

As technology evolves and innovations drive forward, the applications and efficiencies of glass laser cutting will continue to expand. Embracing the possibilities of laser cutting technology is not just about improving production processes. It’s about unlocking new opportunities for innovation and creativity in manufacturing.